Kontaktieren Sie uns

Nutzen Sie unser Kontaktformular, um Angebote oder eine Live-Demo anzufragen, Unterstützung bei Ihrer individuellen Anwendung zu erhalten oder allgemeine Fragen zu stellen. Wir freuen uns auf Ihre Nachricht!

Mech-Eye industrielle 3D-Kameras

Mech-Vision Bildverarbeitungssoftware

Mech-Viz Programmierumgebung für Roboter

2025-05-29

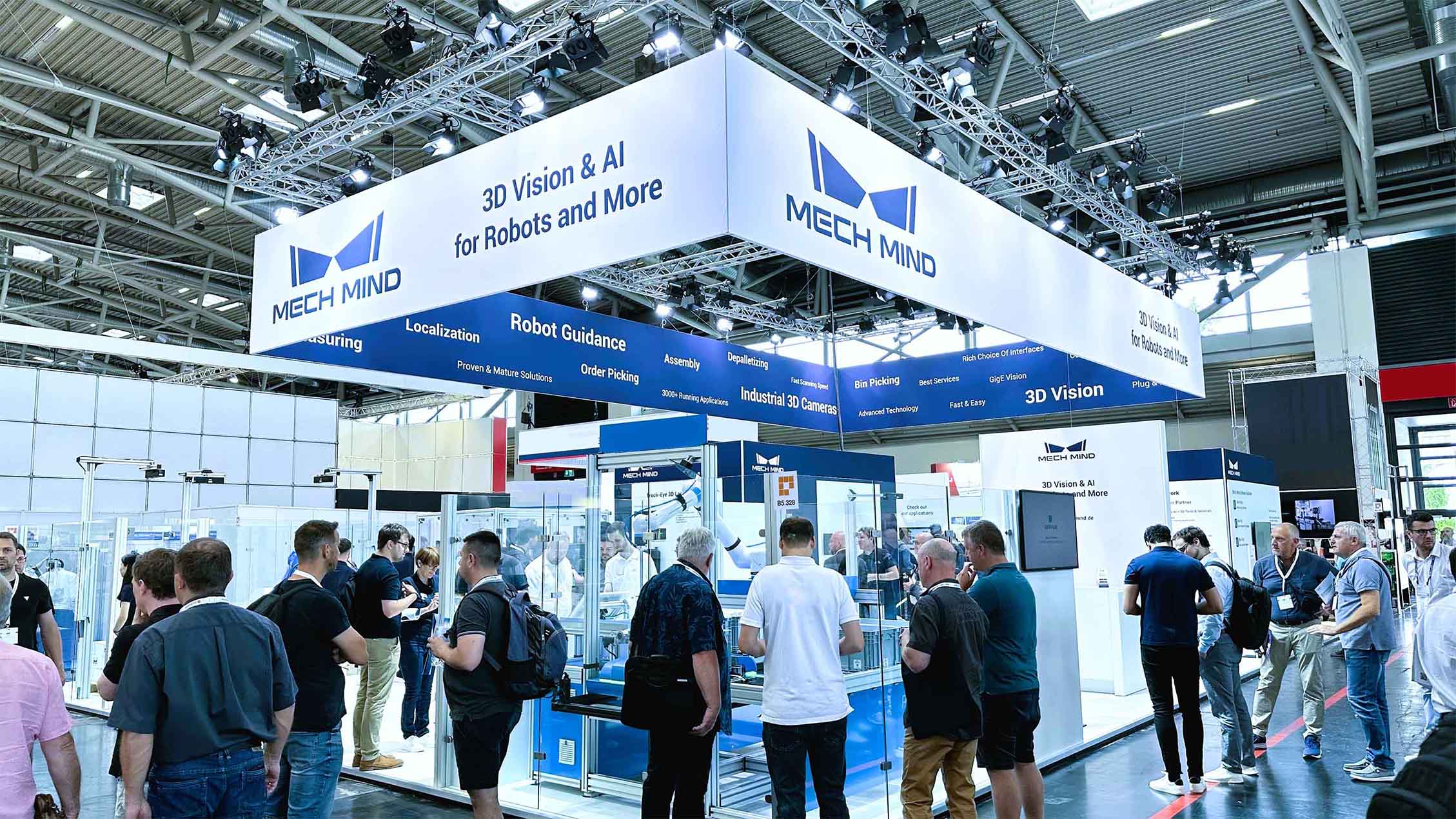

Mech-Mind eröffnet Showroom & Training Center in München: Ausstellungen, Schulungen und Konferenzen zum besseren ServiceIn jüngster Zeit wurde Mech-Mind Showroom & Training Center in der Industriestraße in Germering von München offiziell in Betrieb genommen.

2025-05-27

Mech-Mind auf Automate 2025 | Gewinnt Branchenanerkennung für fortschrittliche KI + 3D Vision RobotertechnologienVom 12. bis 15. Mai fand die Automate 2025 im Huntington Place in Detroit, Michigan, USA, statt.

2024-11-29

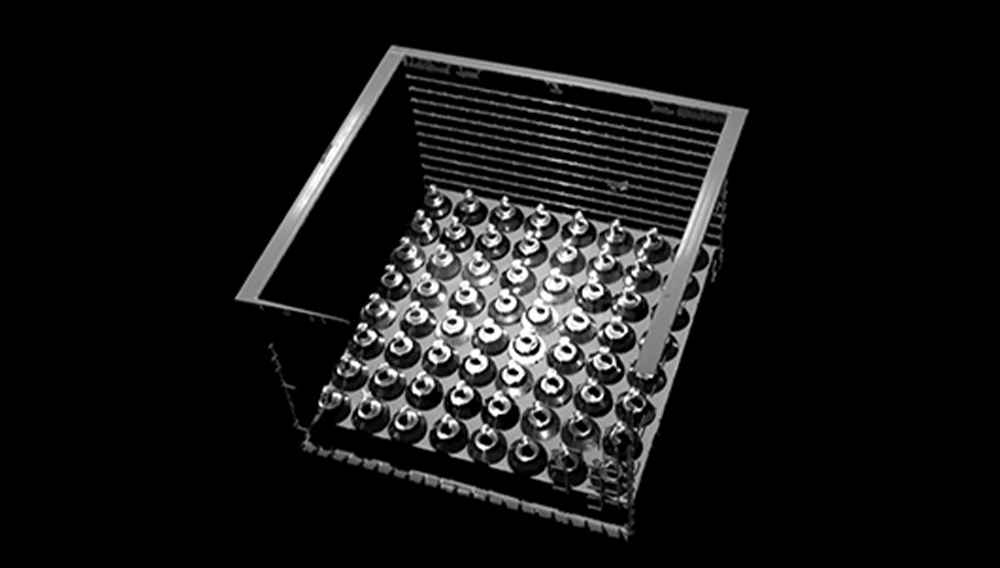

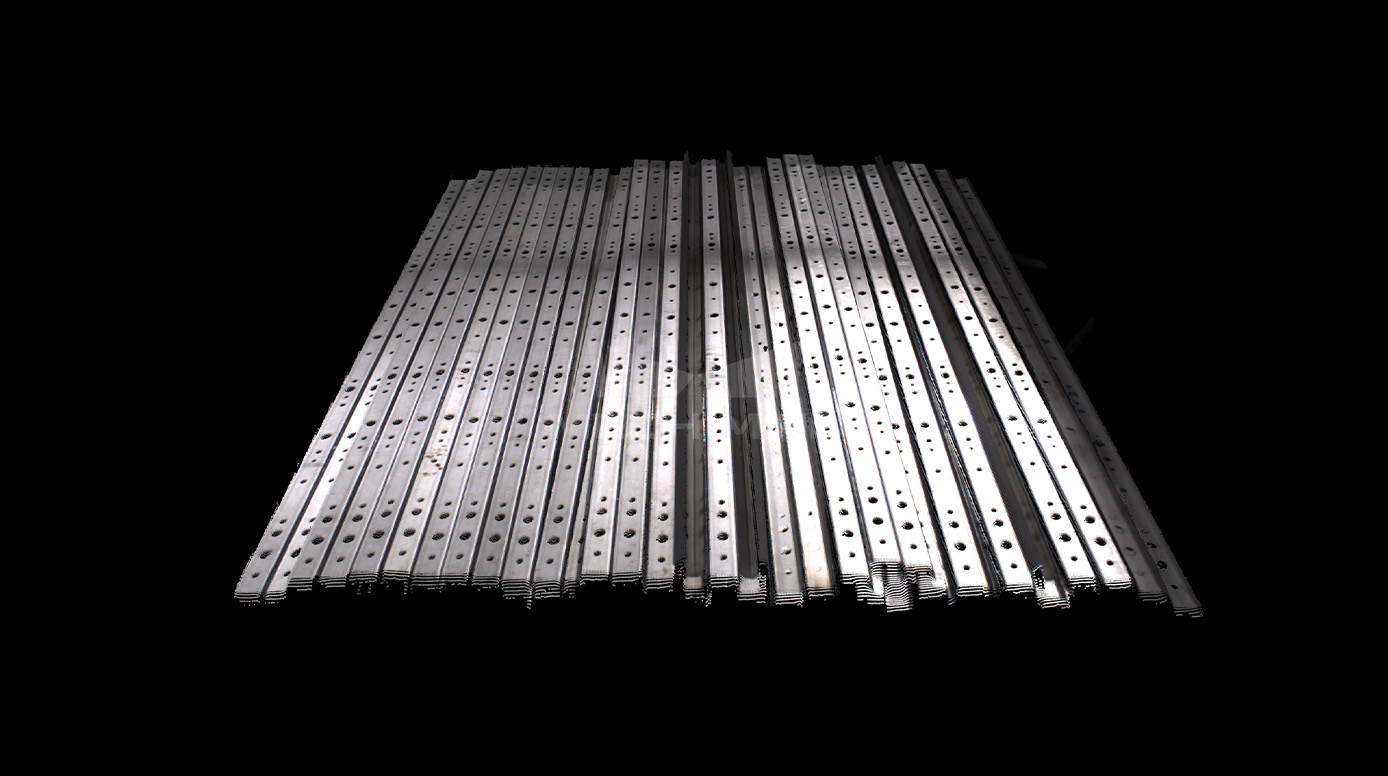

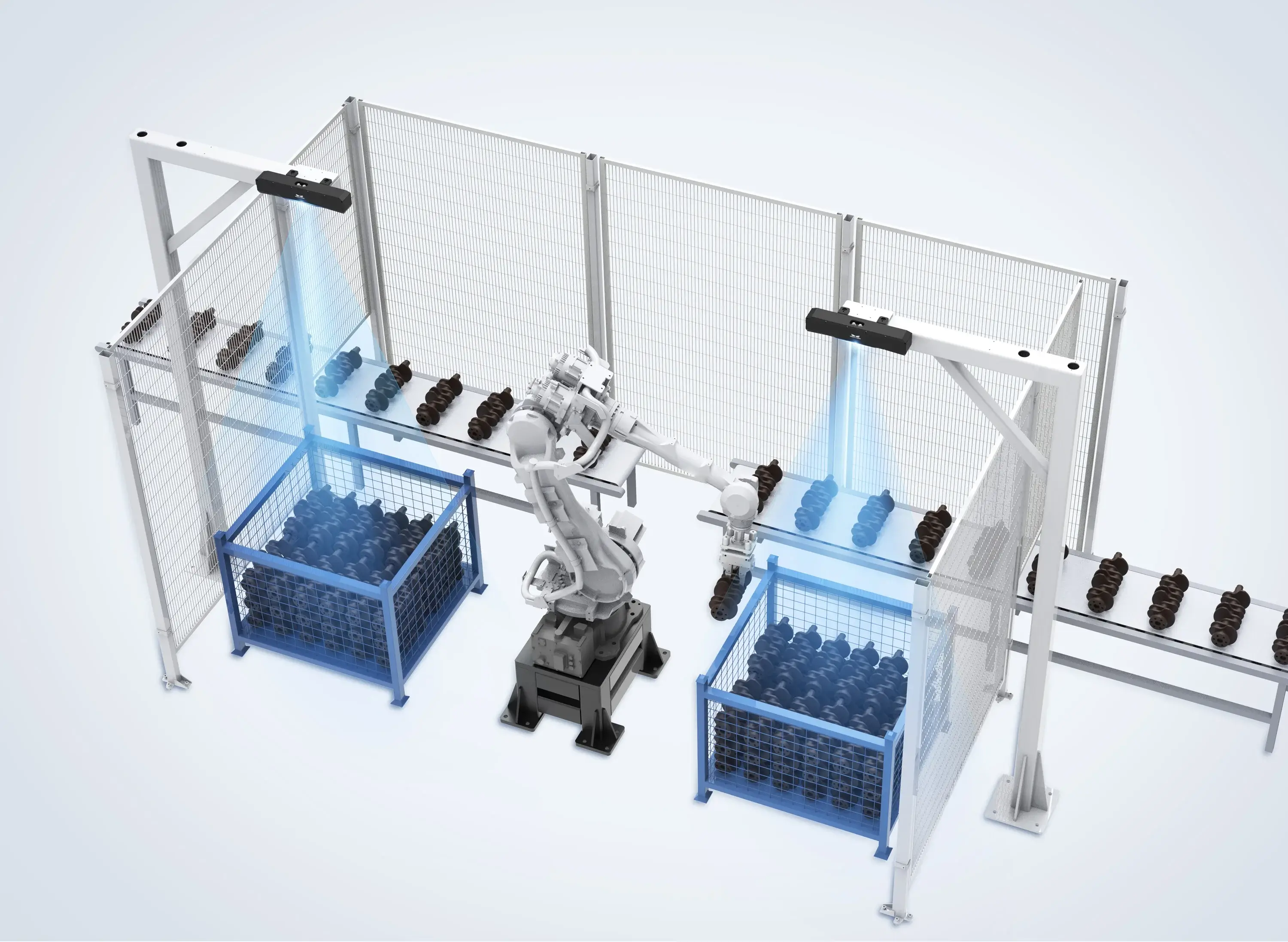

Die Vorteile von 3D-Scannern in der robotergesteuerten KommissionierungDie Kommissionierung ist einer der am schnellsten wachsenden Bereiche für Roboteranwendungen. Sie ist seit einigen Jahrzehnten ein Teil der Fertigungsprozesse, der zunächst von Menschen durchgeführt wurde und nun zunehmend von Robotern übernommen wird. Auch wenn die Kommissionierung ohne 3D-Scanner möglich ist, gibt es einige Situationen, in denen eine extrem genaue Bildgebung mit Kameras, wie z. B. den Mech-Eye Industriellen 3D-Kameras, eine entscheidende Rolle für eine genauere und zuverlässigere Kommissionierung spielen kann.

2024-10-29

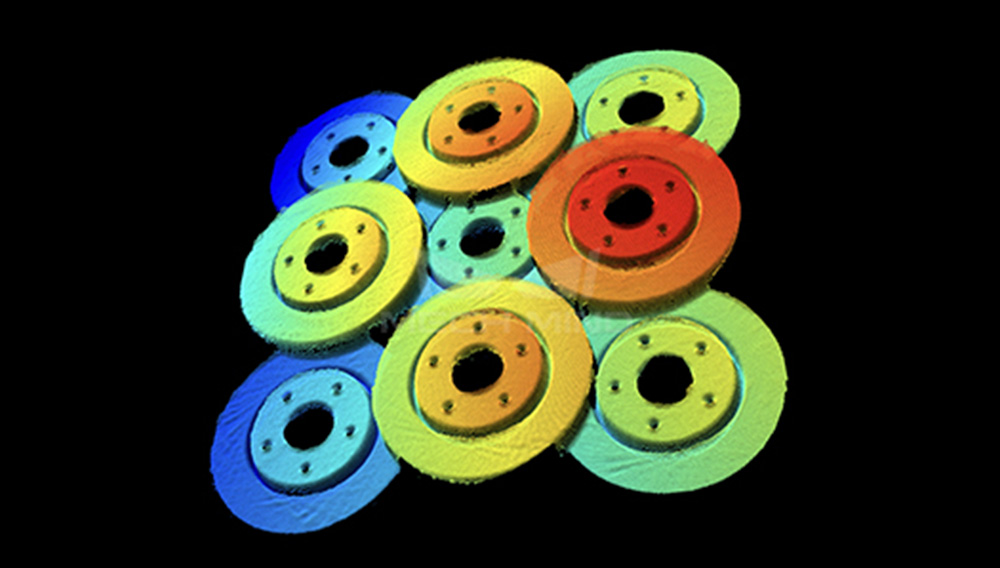

Vereinfachen Sie Ihre 3D-Vision mit Mech-Minds eingebauter ParametermagieBei Mech-Mind sind wir der Meinung, dass die Konfiguration eines 3D-Vision-Systems keine übermäßige Herausforderung darstellen sollte. Um den Prozess zu vereinfachen und die 3D-Vision-Konfiguration benutzerfreundlich zu gestalten, haben wir die Built-in Parameter Groups bzw. die eingebauten Parametergruppen eingeführt. Diese Funktion strafft systematisch die inhärente Komplexität der Konfiguration von 3D-Vision-Systemen.

2024-09-25

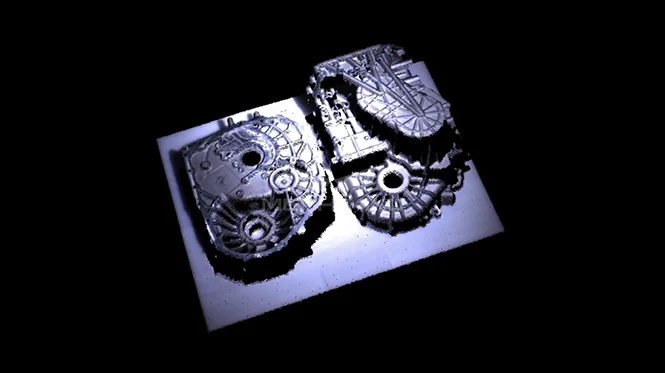

Herausforderungen für 3D-Vision in Picking-Systemen3D-Vision-Systeme werden zunehmend zu einem festen Bestandteil der Fertigungsindustrie. Mit ihren analytischen Fähigkeiten unterstützen diese Systeme die Qualitätssicherung und die Fehlersuche in der Produktion. Durch die Steigerung von Produktivität und Effizienz verbessern sie die Produktionslinien über den gesamten Lebenszyklus hinweg. „Picking" – also das automatisierte Greifen von Objekten – mag so einfach erscheinen wie Erkennen, Entnehmen und Platzieren. Aber in jeder Phase des Picking-Prozesses treten Fehler auf, die zu erheblichen Unsicherheiten bei der Handhabung von Objekten führen. Deshalb müssen einige wichtige Herausforderungen bewältigt werden, bevor die Vorteile der 3D-Vision voll ausgeschöpft werden können.

Nutzen Sie unser Kontaktformular, um Angebote oder eine Live-Demo anzufragen, Unterstützung bei Ihrer individuellen Anwendung zu erhalten oder allgemeine Fragen zu stellen. Wir freuen uns auf Ihre Nachricht!