Contour guided gluing of hatch doors

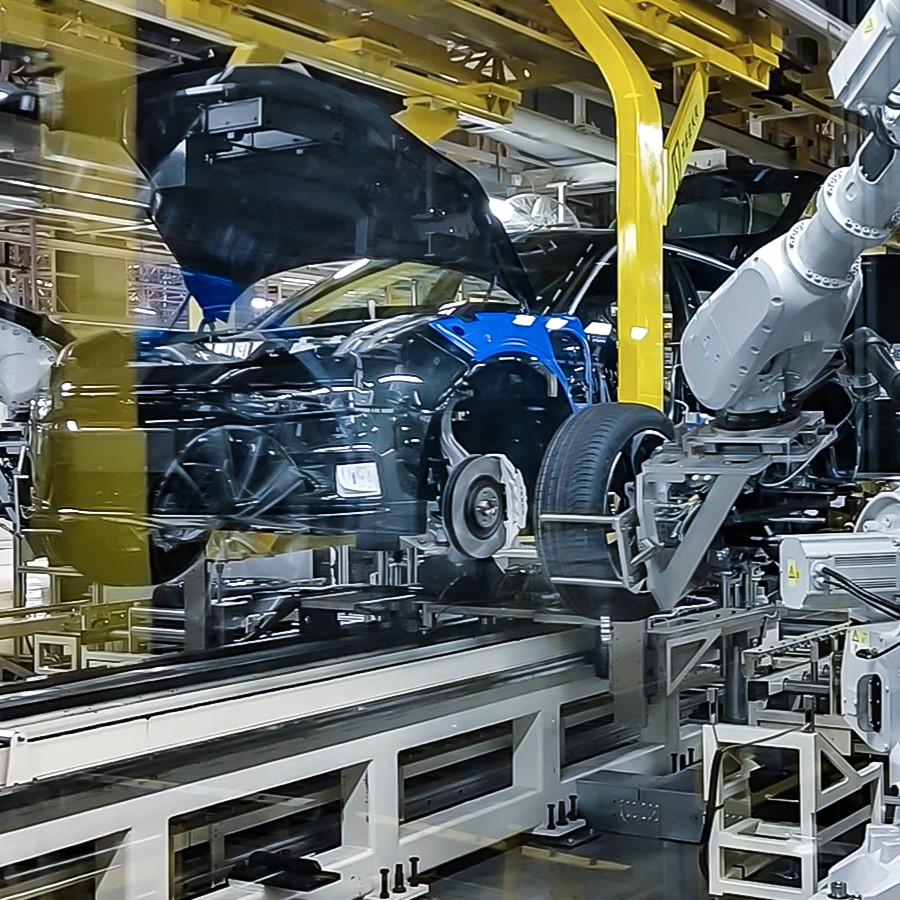

Industry: Automotive Production

Case Study

Customer demand

The hatch door is one of the standard parts in the automotive industry. In this project, the application of adhesive to the components was to be automated. Traditional industrial robots can perform adhesive work at fixed positions and fixed defined lines. Due to the variety of hatch door models in this bus factory, the previous deterministic approach to automation, was out of the question. The customer wanted an automation solution for gluing that could cope with the large number of different product variants. For this purpose, a 3D vision-guided application was implemented, which follows the contours of the parts.

Challenges

- Large product variety

- High precision required

- Large working distance between 3D camera and parts

The Mech-Mind solution

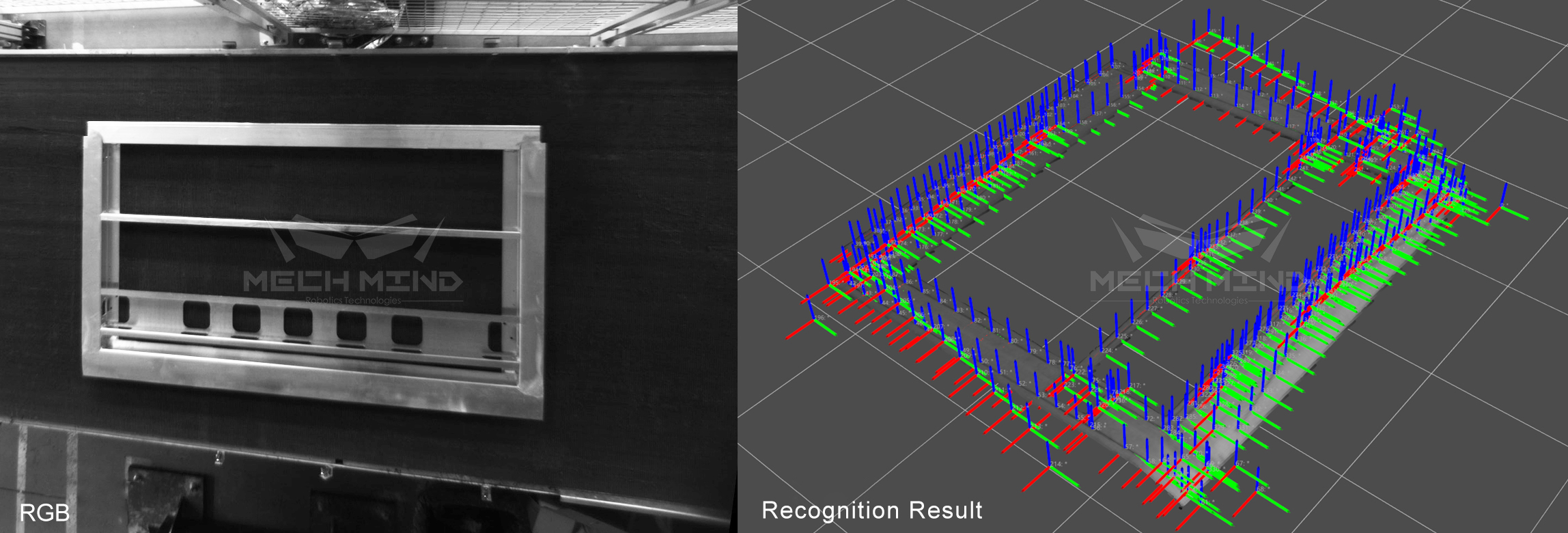

The Mech-Mind 3D camera was mounted above the work surface and captures the entire work area through the large "Field of View".

The Mech-Mind 3D vision system detects and locates the hatch doors on the work surface, identifies the gluing points and guides the robot arm based on the contours.

The high quality point clouds allow high precision glue application of ±1 mm at a working distance of 2.5 meters.

Results

- The 3D vision-guided system follows the contours of the door frames and therefore adapts to new types of hatch doors.

- The parts do not have to be inserted into special holding fixtures, which saves costs and time.

- Consistently high accuracy during bonding is ensured.

3D Vision

In Automotive Production

Want to know how 3D cameras can improve your automotive production? There are endless possibilities - and we've compiled the most important ones in this guide:

- 5 typical applications

- 5 detailed use cases, including challenges & solutions

- 8 more use case examples

Contact