Bin Picking of CV Joints

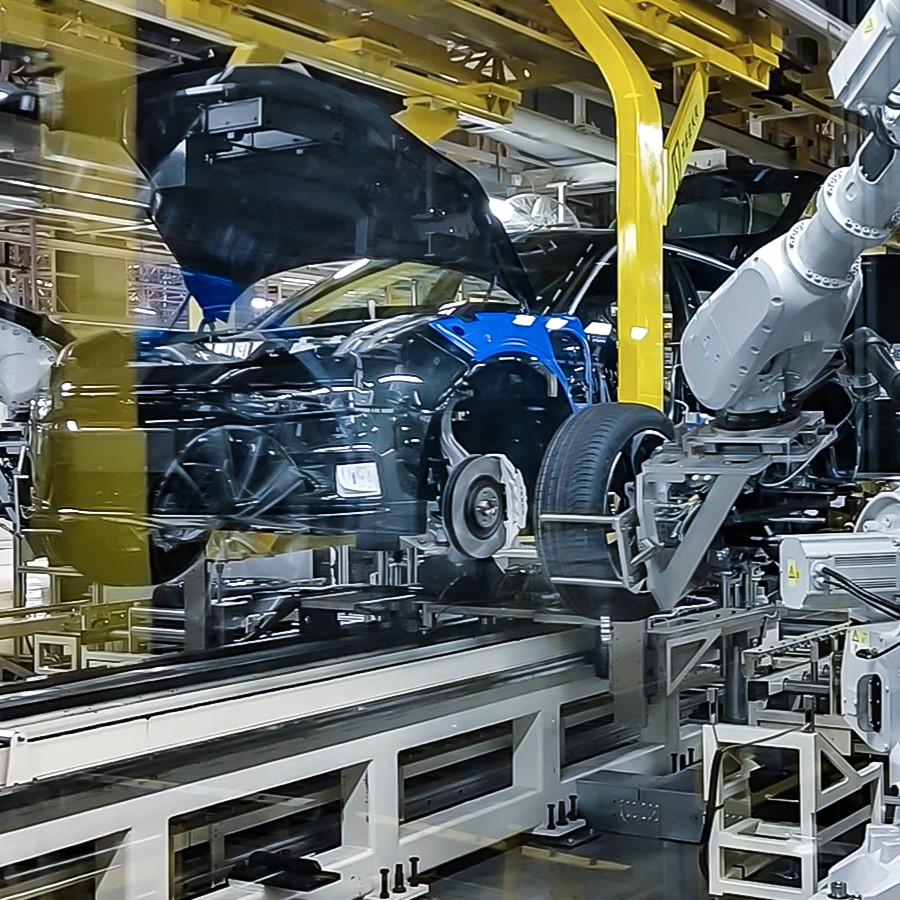

Industry: Automotive Production

Case Study

Customer demand

This customer is a large supplier to the automotive industry. The on-site work environment is harsh and noisy, and the labor-intensive manual operation contributes to high costs and low efficiency. Components for CV joints must be picked from a bin and separated. A 3D vision-guided robot picks the parts from a bin and positions them on a conveyor belt for downstream processes.

Challenges

The surface of the CV joints is glossy and the parts were treated with anti-rust oil after processing, which makes them even more reflective. In addition, a variance of different components is processed, which differ in their dimensions.

The Mech-Mind Solution

The implementation with Mech-Mind's 3D vision system offers several advantages to the customer:

High accuracy

The Mech-Eye PRO S 3D camera used is characterized by high accuracy and can generate high-quality point cloud data of CV joints with reflective surfaces and complex structures;

Flexibility with different products

The solution easily handles metal parts with different specifications: 60~120mm bottom diameter, 16~45mm handle diameter, and 80 ~ 500mm height;

Reliable operation

Intelligent collision detection combined with pick strategy: This enables the best pick angle and pick position to improve stability and safety and solve typical problems such as collisions with other workpieces and containers, falling parts, etc.

3D Vision

in Automotive-Production

How can 3D cameras improve your automotive production? There are endless possibilities - and we've compiled the most important ones in this guide:

- 5 typical applications

- 5 detailed use cases, including challenges & solutions

- 8 more use case examples

Contact